尋找中美洲 / 台灣產品

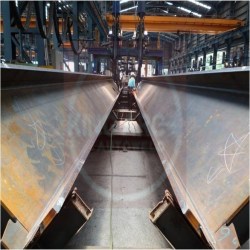

DC/AC Tandem Welding Gantry

Introduction

DC/AC TANDEM WELDING GANTRY

Model: TWG-4015(H)

ADVANTAGE KINGARC

High performance--- this AC-DC submerged arc requires only the electrical supply lines connected to begin production welding process.

Energy saving---Increase arc performance by employing multiple arcs with mechanized electrode positioning and automatic weld controls

Cost saving---The unique torch guidance system assures accurate weld orientation without costly tracking systems

Remote-controlled movable carriages with adjustable torches

High efficiency--The gantry is a motorized structure that travels on rails and is equipped with all necessary equipment for the welding operation

Automated welding machine used to weld flange and web profiles together to form various beam configurations

Flux auto-recycling system ----provides automatic dispensing, removal and recycling of flux

This is available for pail –packed wire(250/300)---decreasing the frequency of wire replacement and thus increasing welding efficiency

SPECIFICATIONS

Power supply 3 Phase /380V/50HZ

Driving system Double DC drive motor and control by only one DC-controller

Travel speed 100 – 5500mm/mim

The distance of the both rail: 4000mm

Height of Web: 300 – 1200mm (2 H-Beam in one time),MAX1600mm(only one Beam)

Thickness of Web: MIN 6mm

Material: carbon steel and high tension steel (according to the flux and wire

Welding position: Flat

Length of travel: 15000 mm

Diameter of wire: 3.2mm-4.8mm (300kgs)

Vertical axle for welding up/down, left/right by AC drive motor

Vertical working range: 400 – 1400mm

Horizontal working range: 400 – 1400mm

Light device: 1Set

H-Beam welding device: 2 Set

WELDING EQUIPMENT

1. Lincoln DC-1500 DC power source (3 Phase 380/440V 50/60 Hz)-- 2SET

2. Lincoln NA-3 wire feeder & controller -- 2SET

3. Lincoln AC-1200 AC power source (1 phase 380V/50 Hz)-- 2SET

4. Lincoln NA-4 wire feeder & controller -- 2SET

5. Lincoln K219 Flux hopper -- 2SET

6. Welding cable and cable car Device(Length:15M)--4SET

7. Ground cable (10M)-- 4SET

FLUX RECOVERY SYSTEM

1. Hitachi 2.5 HP BLOWER -- 2SET

2. Primary Separator Tank & Cone Bucket -- 2SET

3. Recovery hose -- 2SET

CONTROL SYSTEM

Gantry For/Rev,

Travel speed stepless adjustment

Vertical axle Up/Down, Right/Left

Welding Start/Stop,Man/Auto

Recovery system Start/Stop

Flux Hopper ON/OFF

DC/AC start/stop weld

Optional Equipment

1. Conveyor

2. Rail

3. Wire pail device

Company Kingarc Autoweld Co., Ltd.

Tel886-3-3502467

E-Mail info-kingarc@umail.hinet.net

Website http://www.kingarc.url.tw